Select a product from the store and jump directly to its corresponding explanation below.

The core of the Aceroleon system. A true upgrade that turns a freeze-dryer into a measurement and control instrument. Provides real-time sensing, scientific visualization, and precise heater modulation.

This module unlocks:

Provides the controller with smooth, zero-cross heater control. Eliminates harsh on/off relay cycling. Dramatically improves thermal stability during sublimation.

A full electrical monitoring system that measures voltage, current, wattage, power factor, and total energy usage in real time.

Legacy Pressure Gauge Channel – Pressure output with analog amplification for full Harvest Right compatibility and troubleshooting.

High-Precision Pressure Sensor Channel (New) – Dedicated ultra-low-noise 24-bit ADC at the sensor captures subtle variations down to ~0.24 nV — matches performance of high-end industrial/scientific controllers.

In-Chamber Mass / Sublimation Rate Channel (New) – Second ultra-low-noise 24-bit ADC for real-time sublimation rate monitoring with ~1 g resolution.

Legacy DV-4D Gauge Channel – Analog amplification for the DV-4D thermocouple vacuum tube, providing wide native range (0.01–20 Torr), economical sourcing, and full compatibility with standard Harvest Right systems for easy upgrades, restorations, or troubleshooting.

High-Precision Pressure Sensor Channel (New) – Dedicated ultra-low-noise 24-bit ADC at the sensor captures subtle variations down to ~0.24 nV — matches performance of high-end industrial/scientific controllers.

In-Chamber Mass / Sublimation Rate Channel (New) – Second ultra-low-noise 24-bit ADC for real-time sublimation rate monitoring with ~1 g resolution.

A technical deep dive into the physics, control strategies, and failure modes of freeze drying. Written for advanced hobbyists, engineers, researchers, and anyone who wants to understand the science behind optimal freeze-drying cycles.

Coming Soon — available for preorder.

Freeze drying doesn’t have to be blind. The Aceroleon Controller transforms a standard freeze-dryer into a scientific instrument — one that measures, analyzes, and controls the full thermodynamic state of a batch in real time.

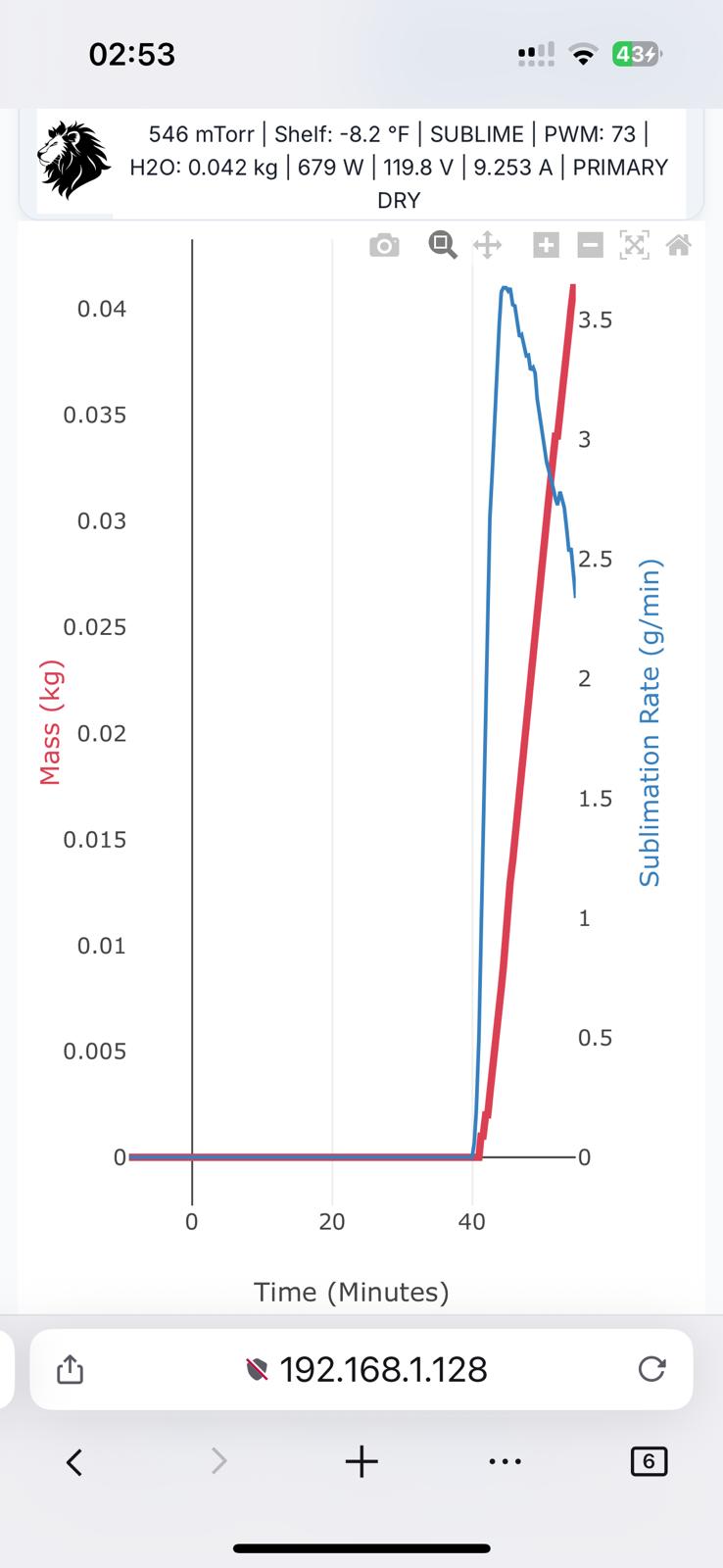

The controller calculates the sublimation rate in real time by analyzing temperature, pressure, and mass data. Even without a load cell, it uses thermodynamic modeling to accurately estimate water loss throughout the run.

This lets you see exactly how quickly ice is leaving the product and whether sublimation is slowing down or stalling. No guessing — you get real scientific feedback about what’s happening inside your freeze-dryer.

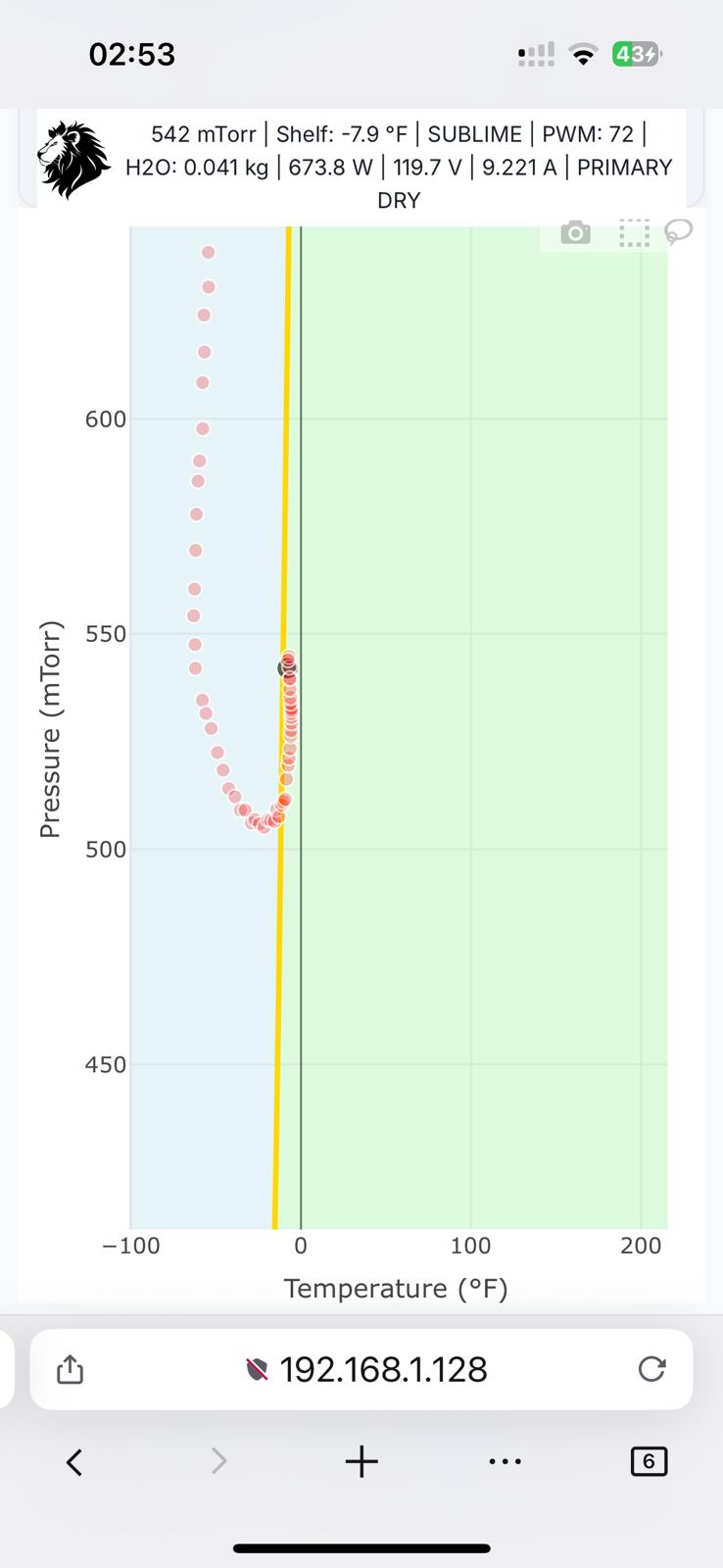

Think of it as GPS for freeze drying. The controller plots temperature and pressure directly onto the phase diagram of water, so you can see exactly where your product sits in the freeze-drying process — in real time.

This visualization gives you scientific insight that no consumer freeze-dryer provides. You can diagnose problems, refine recipes, and repeat successful cycles with confidence.

Most freeze-dryer owners rely on a Kill-A-Watt meter plugged into the wall. It provides real-time numbers, but it has two major limitations:

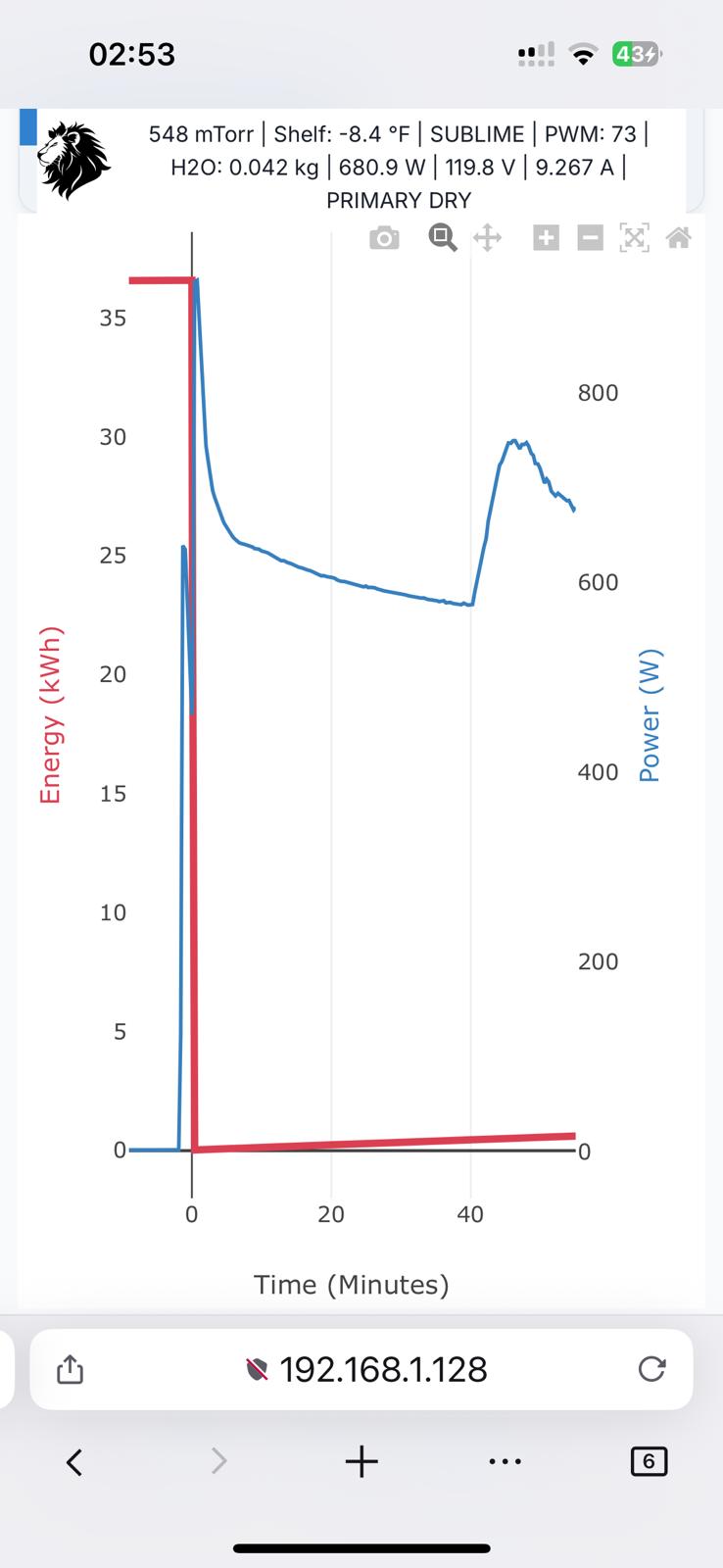

The Power & Energy Module replaces and surpasses a Kill-A-Watt by integrating electrical monitoring directly into the controller — continuously logged, graphed, and synchronized with the entire drying cycle.

Historical electrical data is invaluable for diagnosing heater performance, compressor loading, and unusual energy spikes. You can see exactly when the system is working, how heavily it’s working, and how load changes during sublimation.

Monitoring current also protects your hardware and home wiring. If a freeze-dryer is approaching or exceeding the breaker or outlet rating (15A, 20A, etc.), the controller can alert you long before damage or your circuit breaker trips.

The result: deeper insight, safer operation, and energy tracking that a standalone plug-in meter simply cannot provide.

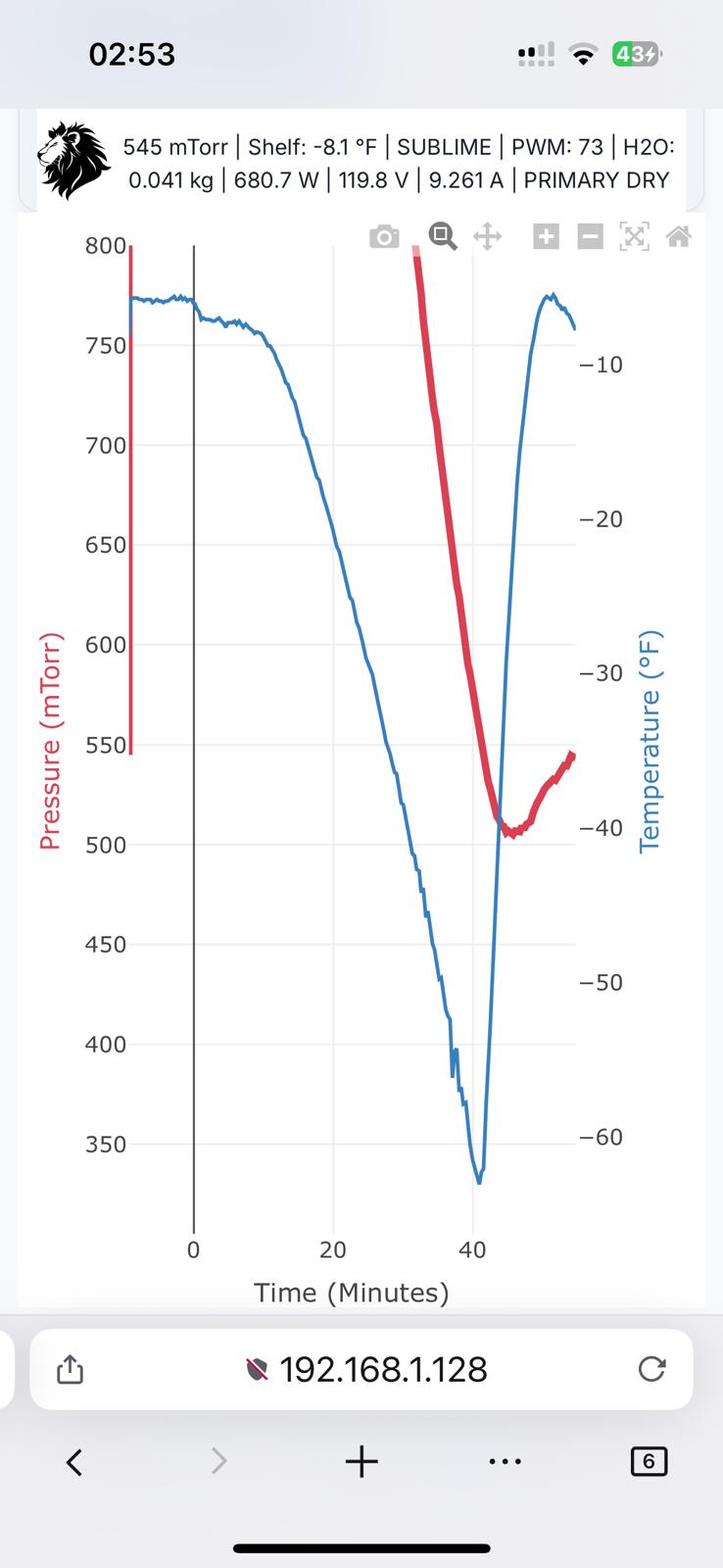

Temperature and pressure are the two most important variables in freeze drying. Most consumer freeze-dryers provide only a single chamber temperature and a basic vacuum reading — often slow, noisy, or inaccurate.

The Aceroleon controller provides high-resolution, real-time monitoring with:

Accurate temperature and pressure curves tell you exactly when freezing completes, when primary drying starts, how efficiently sublimation is occurring, and whether vacuum performance is degrading. This is the foundation of scientific, repeatable, predictable freeze drying.

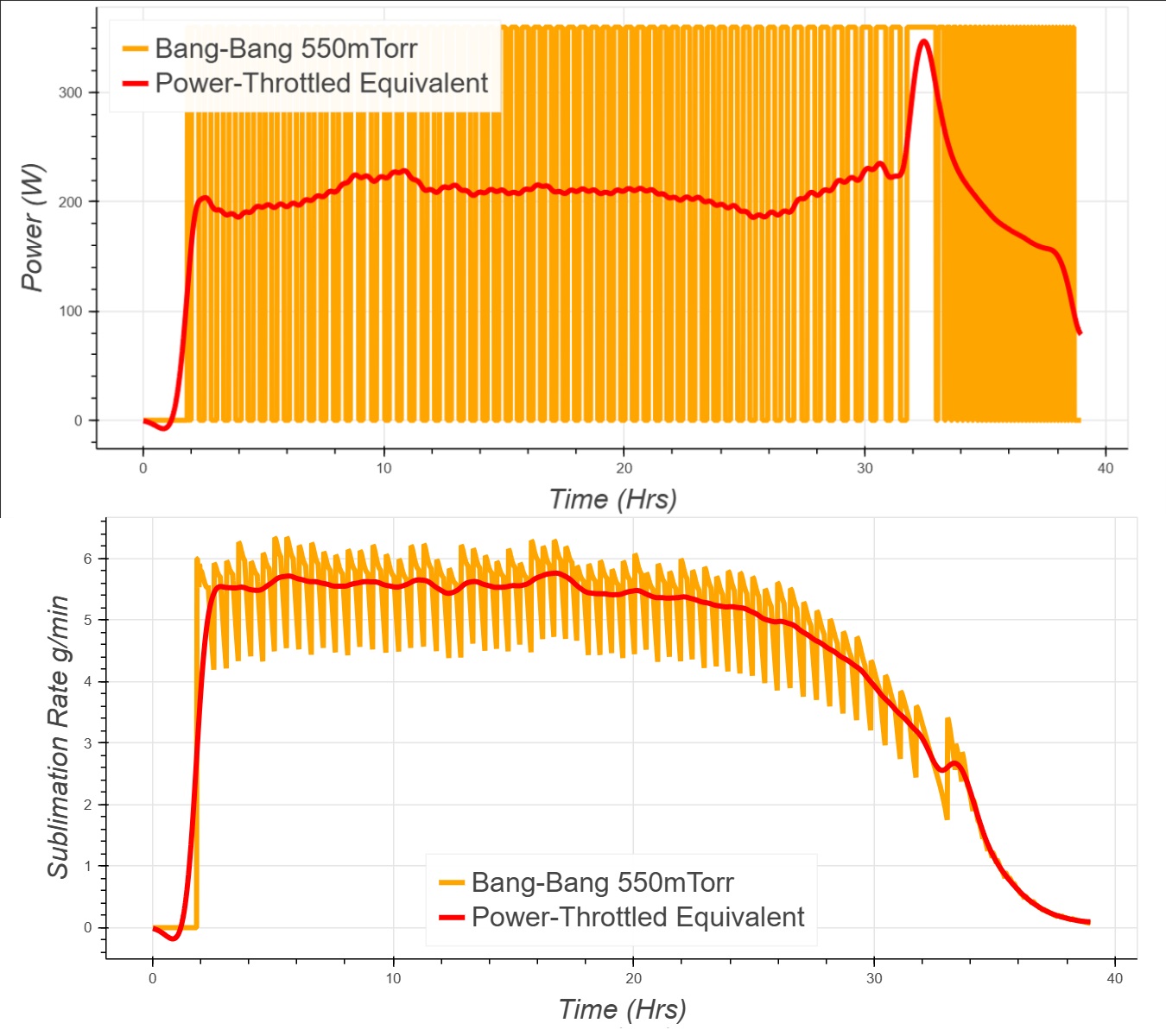

Most freeze-dryers use bang-bang heating — the heater is either fully ON or fully OFF. This creates large temperature swings, unstable sublimation, and constant relay clicking.

The Aceroleon Controller replaces this with smooth, continuous power modulation using an AC snubber network and Schmitt-trigger driver. The result is a stable, controlled heater that does not cycle violently.

On the same load, bang-bang heating produces violent oscillations in sublimation rate — while snubber-modulated heating delivers a smooth, steady drying profile.

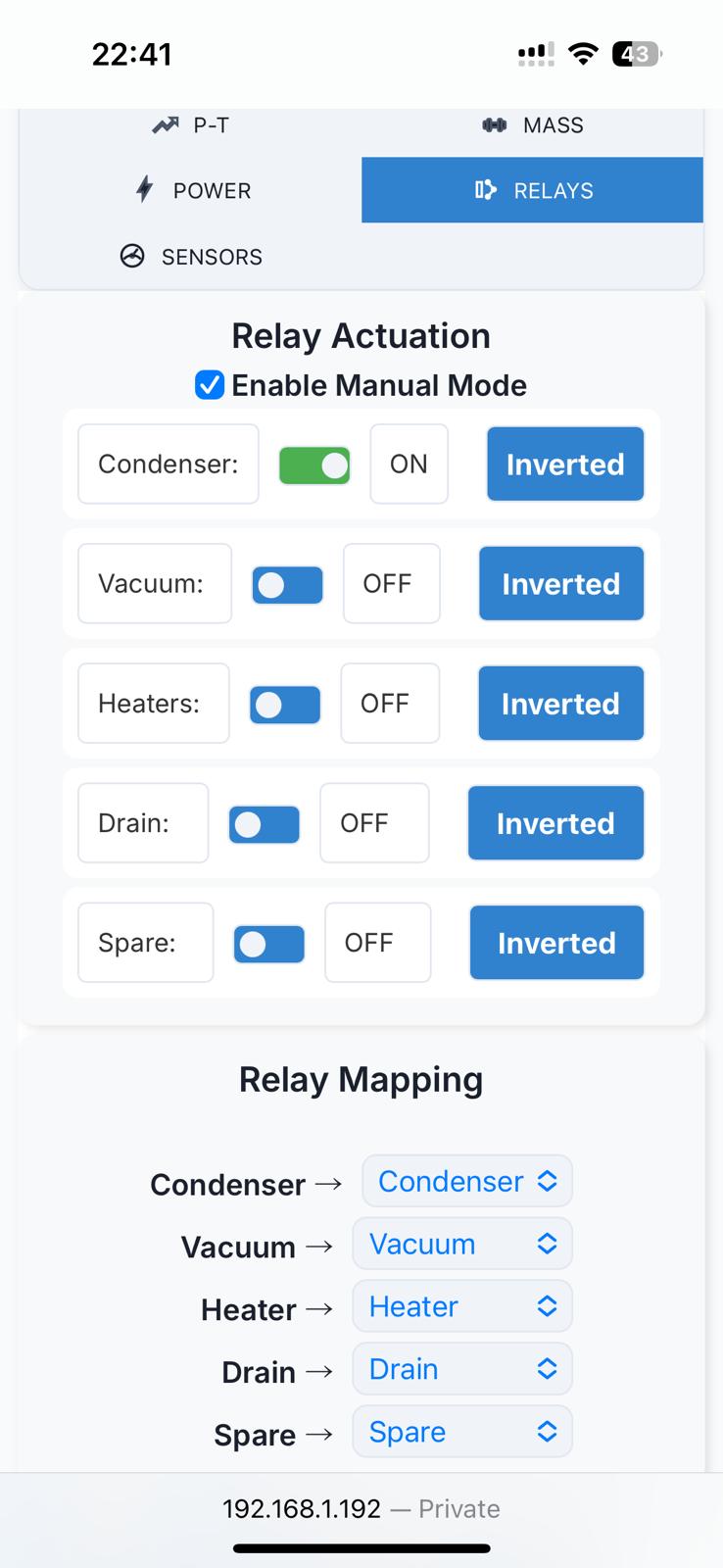

The controller gives you complete control over every major subsystem in the freeze-dryer, without guesswork.

All settings are adjusted directly from the touch-friendly interface, making configuration fast, clear, and reliable.

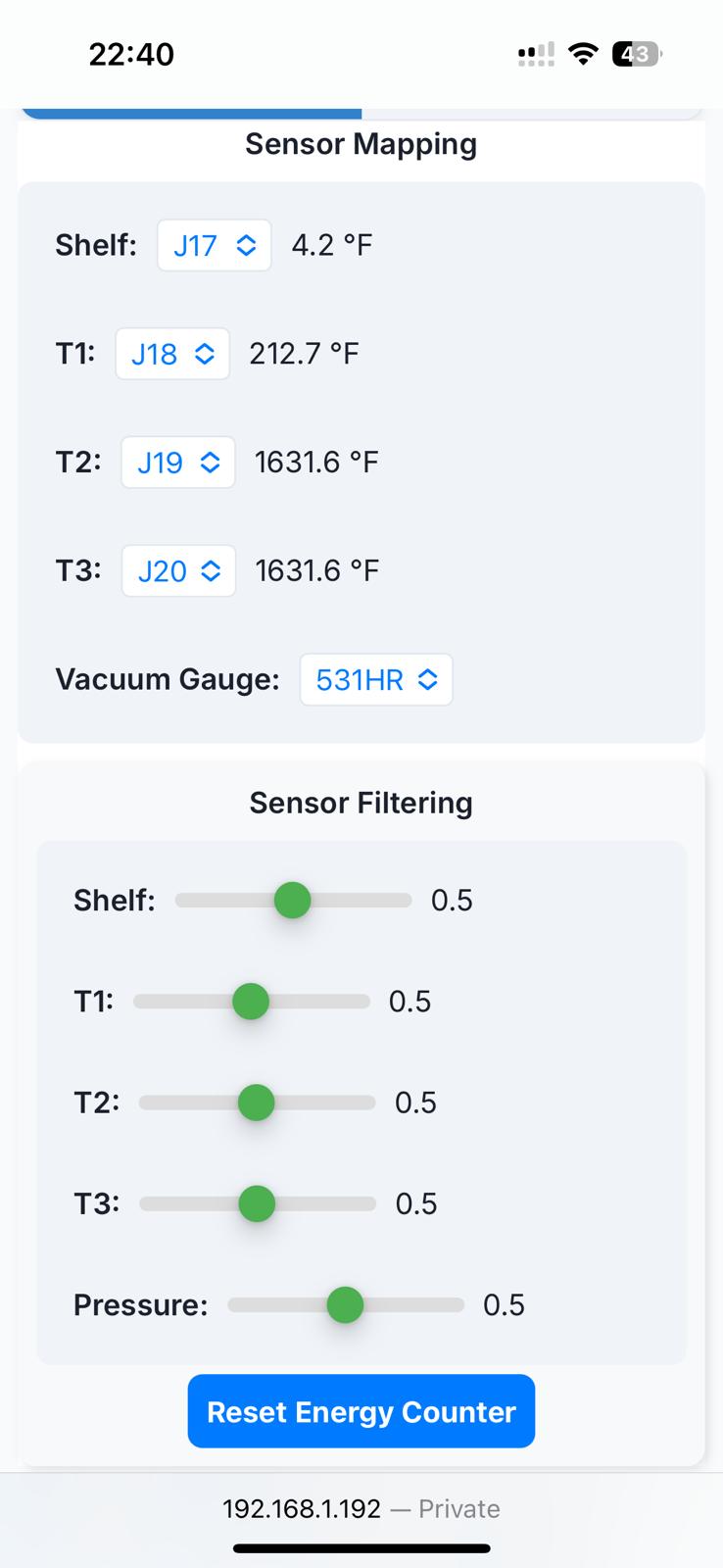

The controller gives you complete flexibility in how sensors are assigned and how their signals are processed—ideal for both standard and custom-built freeze-dryers.

All configuration is done directly through the touch-friendly interface—no coding, no rewiring, no complexity.

The controller includes engineering-grade diagnostics to help you verify system performance and quickly identify issues.

Whether you’re an enthusiast or a professional operator, these tools provide insight, confidence, and a scientific understanding of your freeze-dryer’s behavior.